For us, the focus is on solving your transport task. This requires comprehensive customer support from experts with a proper understanding of the details of your supply chain.

WALTHER Faltsysteme

We are your partner

We stand for plastics competence

More than 45 years of experience in the design, toolmaking and production of reusable load carriers make us specialists in the development of new customised transport containers. We combine all production steps from brainstorming and design to toolmaking and series production in plastic injection moulding under one roof. A load carrier is no longer just about transporting goods safely to their destination - load carriers are now active participants in supply chains. From barcode or smart label identification to special base designs for intralogistical and complex conveyor systems, to recesses in the container walls for handling in automated processes, a load carrier today must not only be adapted to the product, but above all to the processes.

So it's about much more than just a load carrier: Together, we design your logistics process to be more efficient, resource-saving and sustainable - with a customised container for your requirements.

Innovative. Foldable. Sustainable.

Our slogan "Innovative. Foldable. Sustainable." reflects the three most important qualities WALTHER Faltsysteme stands for. We embrace innovation and keep developing new products. Even if not all of our products are foldable today, volume reduction is our brand essence and describes where we come from. Sustainability is firmly anchored in our DNA and an important focus for our future. How we fill this slogan with life and what it means for our brand essence is also described in our mission and vision.

We continuously develop new ideas in order to optimise the logistics of our customers with new products. Due to the increasing digitisation and automation in packaging logistics, both our customers and we as manufacturers are faced with completely new challenges. New technologies also mean new possibilities and opportunities for innovative applications along the supply chain. We want to be your reliable partner to meet the challenges of the future.

Mission and vision

Our mission

We develop innovative reusable load carriers for sustainable logistics. We are packaging developers who provide the right reusable container for your transport or storage task using all available technologies. That's why we are the right partner for your multi-trip logistics.

Our vision

Through volume-reducible load carriers, we make global logistics processes more efficient, save resources and actively contribute to the preservation of our planet. We embrace innovation, develop sustainable products and assume social responsibility. We are the leading specialist for customised reusable plastic load carriers. We set technological standards.

History

Plastic containers with a tradition

To us, tradition does not mean that we have been making our containers the same way for 45 years. To us, tradition means expertise. Commitment to innovation. Responsibility for our work. As a medium-sized business, we are always focussed on the market. We know about new developments in the plastics sector and see how modern container logistics develops.

1978

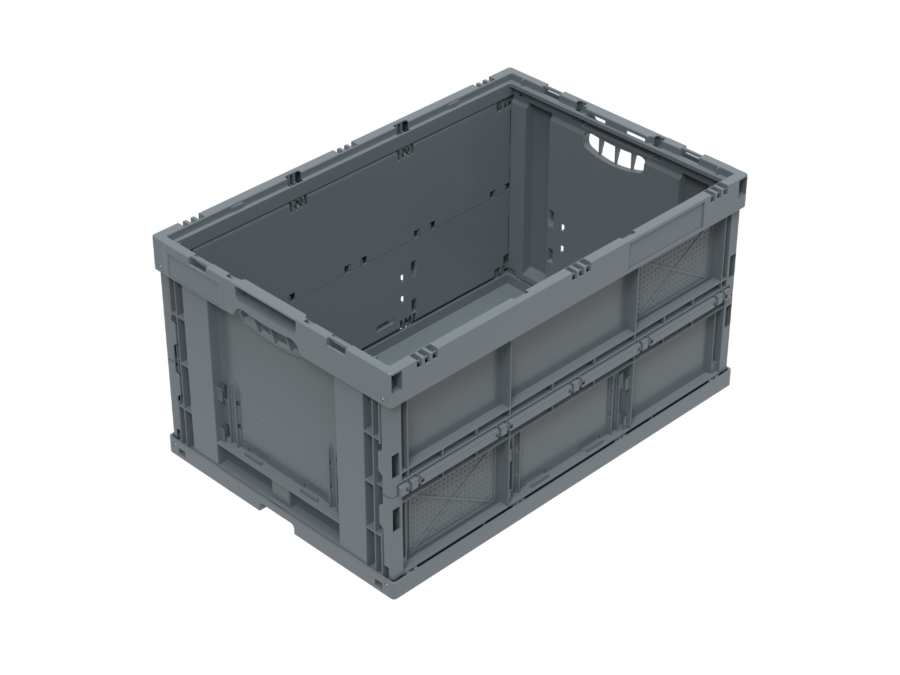

From a business trip to Japan, engineer Rolf F. Walther brings back a foldable plastic container. Inspired by this, he developed the first folding box made of plastic (polypropylene) for the European market in collaboration with an injection moulding company. After the mould and the first boxes have been produced, there are attempts at selling the folding box to private customers – with limited success.

1980

Presentation of the box at the HANOVER trade fair. There, the brand “WALTHER Faltboxen” is registered. The first distributor – PAUL CORBETT Co. Ltd. from England – orders a pallet of boxes in different colours at the trade fair.

1982

With the appointment of Thomas Wiederer as Sales Manager, the systematic marketing of the folding box idea in Germany and Europe begins. Through advertising and participation in trade fairs, the folding boxes become increasingly better known.

1983

More versions of the folding box are developed: 32 l folding box, 40 l folding box, and first bulk orders (more than 1,000 items) are placed by industry and trade customers.

1985

Introduction of the so-called department store shipping tower for the stores of retail chain KARSTADT. Various folding box sizes can be placed onto a mobile base with the basic dimensions 800 x 600 mm. These are then rolled from the central warehouse directly to the shelves in the stores.

1989

Following the KARSTADT example, KAUFRING orders its own despatch tower. The bulk order has a volume of approx. 9 million Deutschmark. The order by KAUFRING is the breakthrough in trade. First contacts with VDO (today’s Continental) lead to a contract for an adaptation of the 60 l folding box with a reinforced base made from conductive PP. Start of the collaboration with RAJA in France.

1990

The product range now comprises more than 35 folding box versions. WALTHER folding boxes are established as reusable foldable boxes in the non-food range of food retailing.

1991

Purchase of larger premises in Kevelaer in the Lower Rhine area, thus establishing a second place of business in addition to Mülheim / Ruhr. Thomas Wiederer is given general commercial power of attorney. The German Packaging Ordinance obliges manufacturers or distributors of packaging to dispose of the same. This makes the reusable foldable WALTHER packaging solutions even more interesting for industrial users.

1992

WALTHER Faltsysteme expands its dealer network in Germany and in the western and northern European countries.

1994

Rolf F. Walther retires as managing partner, his son Thomas Walther is appointed as sole manager.

1996

Certification according to DIN EN ISO 9001. First studies on marketing foldable pallet boxes in lightweight design.

1997

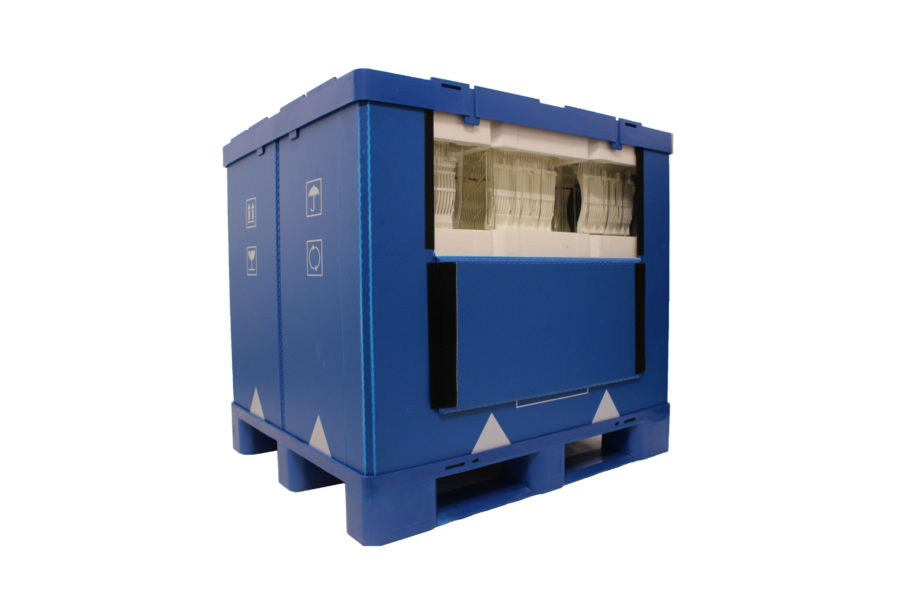

Development of a foldable large container range with the brand name Mega-Pack system, expanding the range of volume-reducible transport containers by the basic dimensions 800 x 600 mm, 1,200 x 800 mm and 1,200 x 1,000 mm.

1998

The retail chain FNAC in France completely changes the supply of its stores to folding boxes and dollies. This cooperation results in the dolly 600 x 400 mm.

1999

The Hybox 1,200 x 800 mm is introduced as a foldable pallet box for food packaging and for use in hygienically sensitive areas.

2000

Introduction of the online shop www.boxline.de, offering more than 2,000 different storage and transport containers made of plastic for industry, trade and commerce.

2001

Launch of a new generation of folding boxes, with optimized hinges and mould technology carrying both higher payloads and stacking capability (NG version).

2002

The Hybox range is expanded by the ISO dimension 1,200 mm x 1000 mm, thus creating new markets. At the suggestion of INFINEON in Dresden and SILTRONIC in Burghausen, an air freight Hybox 1,200 x 1,000 mm is designed in cooperation with the VDZ in Dortmund. This Hybox is still the basis for the Hybox packaging used in the semiconductor industry worldwide today.

2004

Relocation to Kevelaer. Due to the strong growth, the premises are continuously expanded over the following years.

2006

The extension of the Packing Ordinance in 1991 results in the obligation to take back disposable bottles. As early as late 2005, WALTHER develops the first concept packaging for collecting and returning disposable bottles and cans in cooperation with manufacturers of reverse vending machines. With the start on 1st May, 2006, the range of WALTHER Faltsysteme includes an extensive system of collection containers for both automated and stand-alone applications. Start of the collaboration with BEKUPLAST from Ringe as a development and production partner. The drugstore chain MÜLLER changes the supply of all its chain stores to folding boxes and dollies from WALTHER. So far, more than 1.5 million boxes have been delivered to MÜLLER.

2009

Development of an innovative plastic pallet folding frame for Migros in Switzerland. Discount store ALDI SÜD orders 4.5 million foldable fruit and vegetable containers to establish their own multi-trip pool system.

2010

The success story in the retail sector continues – WALTHER Faltsysteme supplies the largest logistics project in Scandinavia with innovative, collapsible reusable boxes.

2011

WALTHER Faltsysteme acquires a substantial share of its main supplier Formex Plastik GmbH. Thomas Wiederer, who has been manager with general commercial power of attorney and sales manager for many years, is appointed Managing Director of WALTHER Faltsysteme GmbH.

2012

Another milestone is reached: for top food retail group REWE, hundreds of thousands of collapsible containers are produced – for the first time from certified recycled material of the Procyclen brand manufactured by interseroh. Sustainability and green logistics are the daily business of WALTHER Faltsysteme.

2012

Introduction of a new retail folding box for fully automated warehouses with special base outline and in-mould labelling.

2013

Certification according to DIN EN ISO 14001 environmental management and DIN EN ISO 50001 energy management.

2015

Opening of the new WALTHER logistics centre with an area for storage, picking and packing, and shipping comprising 2,500 m² to meet today’s standards for fast delivery of a wide product range.

2016

Introduction of a new plastic half pallet to the Austrian retail trade. Start of the new e-commerce folding box eFold with fully automated assembly and innovative printing technique.

2017

Introduction of the Greenline boxes made from recycled polypropylene.

2018

WALTHER Faltsysteme celebrates its 40th company anniversary. Presentation of an innovative container for hanging goods in the textile industry. Expansion of the premises by another 3,000 m² office and storage space. Introduction of a new, future-oriented enterprise resource planning system.

2019

WALTHER Faltsysteme receives the pro-K award of the Industrial Association for Semi-Finished Products and Plastic Consumer Products (Industrieverband Halbzeuge und Konsumprodukte aus Kunststoff) for its Düsseldorf plastic pallet, which sets new standards in transport and intralogistics thanks to its repairability, its outstanding eco-balance and its integrated RFID chip for transmitting location data.

2020

Introduction of the innovative WALTHER roll container to the German market. Receives the internationally renowned “German Design Award” for outstanding product design.

2021

After the German Design Award and the pro-K Award, the roll container with its patented quick-coupling system also receives the German Packaging Award in Gold. This exclusive award is given to particularly groundbreaking innovations.

2021

WALTHER Faltsysteme receives the Top 100 Seal. This innovation award annually honours the 100 most innovative SMEs selected by the jury. WALTHER Faltsysteme regularly develops new multi-trip transport solutions for logistics.

2021

Thomas Walther, son of founder Rolf F. Walther, leaves after 27 years of heading the company. The 63-year old turned a small business into a successful corporation. With him, the second Managing Director Thomas Wiederer also leaves WALTHER Faltsysteme after almost 40 years.

2022

Dominik Lemken and Thomas Heilen will be the new Managing Directors of WALTHER Faltsysteme. The long-serving general managers have already been with the company for eight and 17 years respectively and have proven their abilities in executive positions.

2022

Our roll container receives the Red Dot Award: Product Design 2022. The “Red Dot” award stands internationally for good design quality. The roll container with patented quick-coupling system has now received four prestigious awards.

2022

WALTHER Faltsysteme acquires the majority holding in the injection moulder Formex Plastik GmbH. At the same time, the organisational units are merged. New managing directors are Dominik Lemken, Andre Peters, and Thomas Heilen.

2023

In the course of a tender by Euro Plant Tray eG, WALTHER Faltsysteme designs a reusable plant tray and makes it into the top 2. At the beginning of March, WALTHER delivers the first 20,000 trays to garden centers and wholesalers for a test phase. The Euro Plant Trays are intended to become part of a new European standard for plant trays and to gradually replace the disposable trays, saving several 10,000 tonnes of waste in the future.

Contact us now

You would like to know more about us?

Then please get in touch. We will be happy to answer your questions about our company.