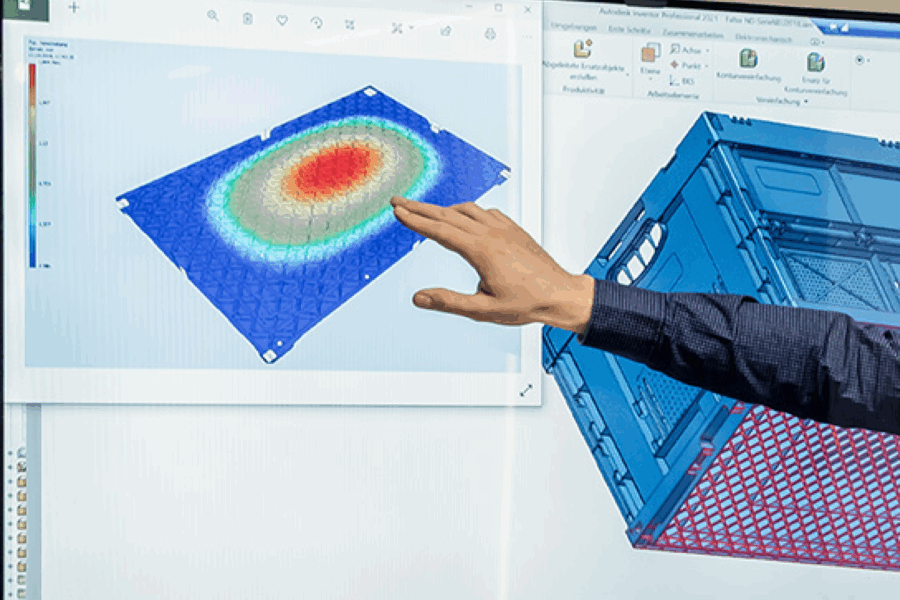

Based on your specific challenges in your logistics process, we develop customised storage and transport containers to meet your individual requirements.

Based on your specific challenges in your logistics process, we develop customised storage and transport containers to meet your individual requirements.

You have special requirements for your reusable transport solution that our standard products do not yet meet? WALTHER Faltsysteme is your specialist for customised plastic containers. We stand for plastics expertise and can draw on over 45 years of experience in the design, toolmaking and production of reusable load carriers.