The storage and picking system ensures fully automated, space-saving and careful placement of items on customised load carriers from WALTHER.

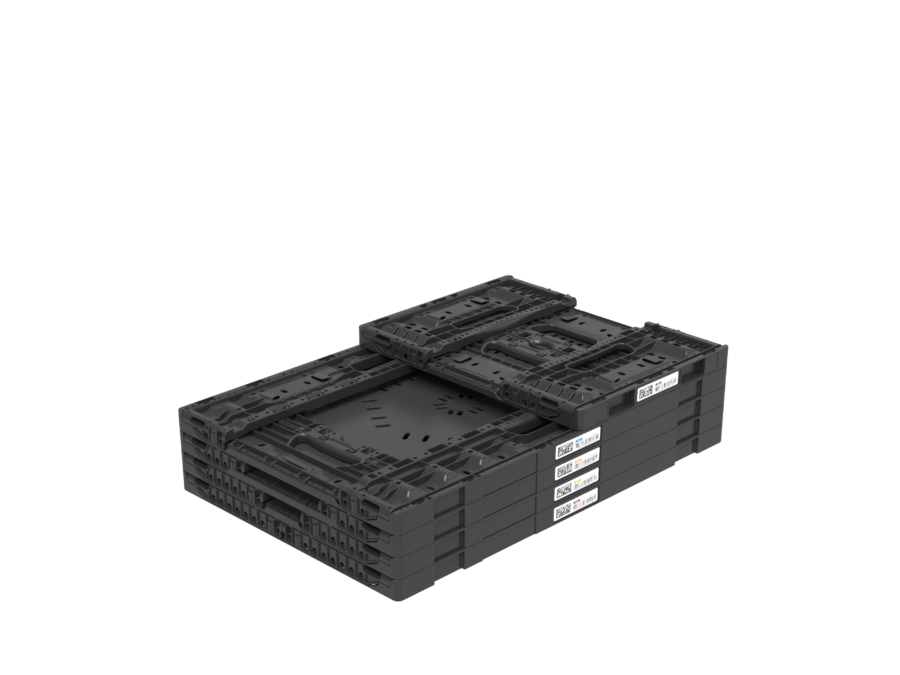

Customised trays made of plastic in use at Migros

Migros Verteilbetrieb AG

Customised load carriers

Sustainability and automation

Migros Verteilbetrieb AG places the utmost importance on sustainability. For the shipping of goods from the warehouse to the store, it uses the OPM storage and picking system from Witron. The system ensures fully automated, space-saving and careful placement of the retail units on load carriers from WALTHER Faltbox Group.

Customised trays for fully automatic order picking

We developed special trays for this type of system, which are also used at Migros Verteilbetrieb AG.

In the warehouse, movement, loading, and storing of the trays is fully automatic. The smooth picking process is achieved by four in-mould labels with an additional side identifier so that the goods are optimally placed in terms of weight and dimensions. Then the goods are lifted off the tray with spikes, pushed onto the appropriate load carrier and transported to the stores.

Several hundred thousand trays in use

The trays are designed for fast transport on the conveyor systems and minimum deflection under load. And due to the space-saving transport and the long service life these trays are sustainable to boot. That is why Migros Verteilbetrieb AG now uses several hundred thousand trays.

Trays by WALTHER Faltbox Group

This is how Migros Verteilbetrieb AG benefits from a customised solution

Individual advice

Do you have any questions regarding our reusable load carriers?

Then please get in touch. Our experts will be happy to advise you individually and help you find the solution you need.

Oliver van Neerven

Director Projects & Technology