With a height of only 27.5 millimetres, the collapsible fruit and vegetable boxes from WALTHER are the flattest in the WBG Pooling assortment and individually tailored to supply growers and food manufacturers.

Collapsible fruit and vegetable boxes in use at WBG Pooling

WBG Pooling

Flattest collapsible box

Sustainable transport logistics with reusable systems

As an experienced pooling provider of reusable transport packaging, WBG Pooling offers full service along the entire food supply chain. In addition to the supply and management of load carriers, the range of services offered by the logistics service provider includes cleaning and disinfection as well as storage, repair and recycling. Through the principle of holistic circular economy, waste is avoided and CO2 emissions are reduced.

Since the end of 2021, the collapsible fruit and vegetable boxes from WALTHER have been part of the WBG Pooling portfolio, which is available to growers and food manufacturers throughout Europe. The collapsible boxes are ideal for the transport and storage of unpackaged fruit and vegetables. As well they are also used as storage carriers for packaged foods such as convenience products.

Collapsible fruit and vegetable boxes in use

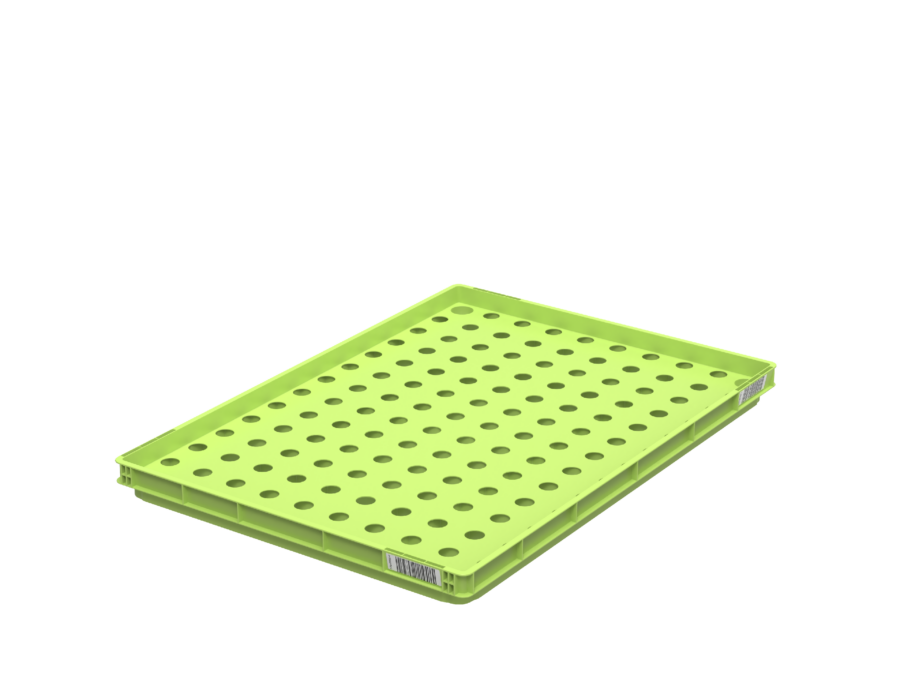

In the collapsible fruit and vegetable boxes from WALTHER, the sensitive food products are safely packed after the harvest and protected from damage. Perforations in the base and side walls ensure good air circulation, which keeps the food fresh for a long period of time. Thanks to their smooth inner surfaces, the collapsible boxes allow easy and hygienic cleaning; remaining water runs off and moisture is avoided.

The innovative "SmartLock" locking system ensures ergonomic and intuitive handling. In addition, it enables fully automated handling of the collapsible boxes during picking and in the washing process.

In WALTHER Faltsysteme we have found an experienced supplier who combines flexibility and innovation. Above all, we value the partnership-based cooperation, which is intended for the long term. Through regular, close exchange, we continuously develop new possibilities together within our supply chains.

Cradle to Cradle® certification for smart reusable packaging

To use resources as efficiently as possible, the design of the box is geared towards durability. Therefore, all elements can be replaced so that the collapsible box can be repaired if necessary. When a load carrier has reached the end of its life after long use and multiple circulations, the material will be recycled and processed into a new collapsible box.

The collapsible boxes are equipped with RFID In-Mould labels, enabling seamless scanning and tracking. This enables automated handling for the pooling service provider. Thanks to the closed, smart loop, WBG Pooling has received the Cradle to Cradle® certification for the product series. As the developer and manufacturer, we were able to support WBG Pooling throughout the certification process with our expertise.

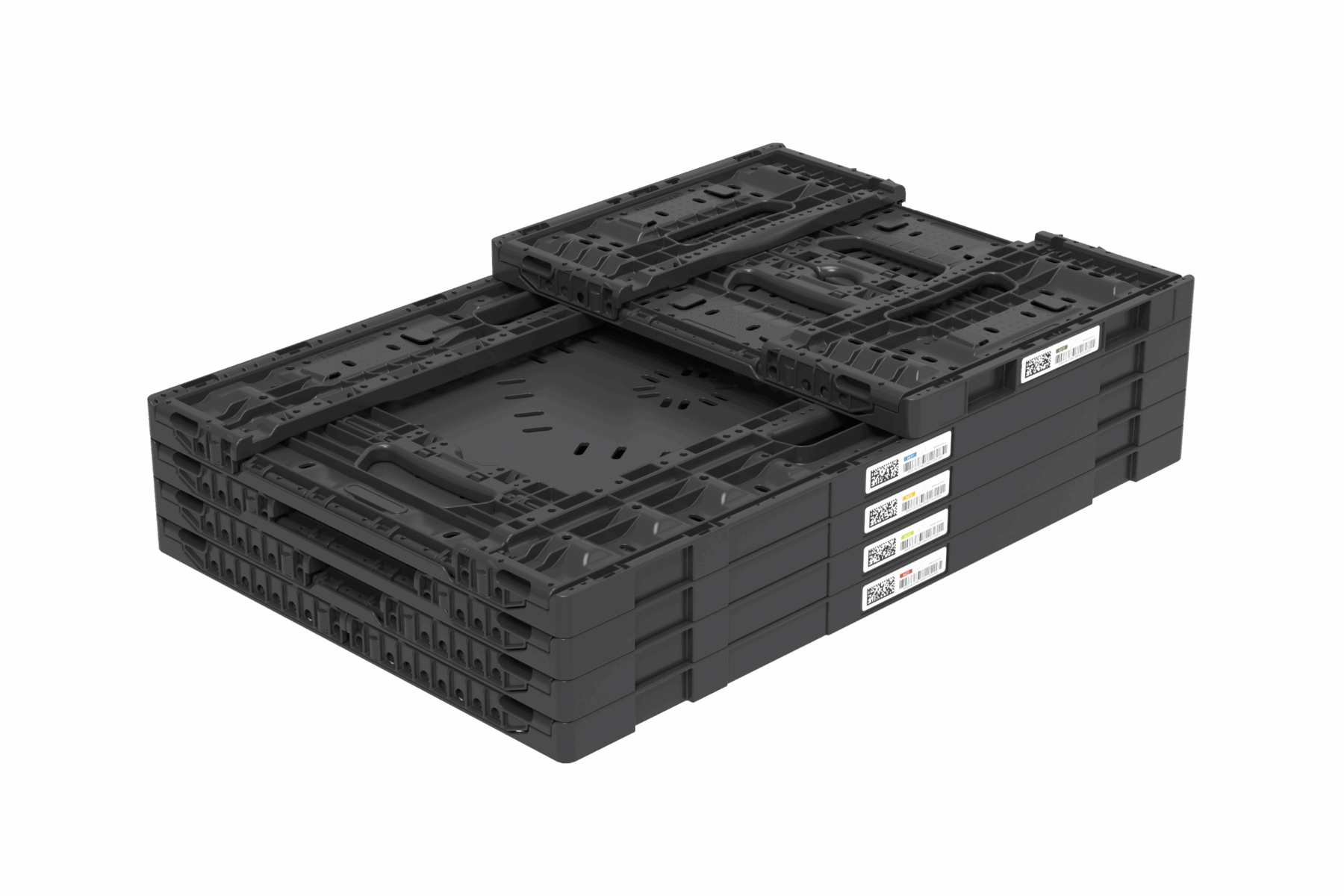

Efficient return and increased eco-balance

The ability to reduce the volume of the collapsible boxes means that the return transport of the empties can be made as efficient as possible. Significantly more load carriers fit into a truck, so that entire truck tours can be avoided. Customers benefit not only from lower transport costs, but also from reduced CO2e emissions.

After being cleaned, the boxes are distributed to the growers again and the journey of our collapsible fruit and vegetable boxes begins all over again.

Collapsible fruit and vegetable boxes from WALTHER Faltsysteme

This is how WBG Pooling benefits from a customised solution

This is how the flattest collapsible box on the market is created

Production of the collapsible fruit and vegetable boxes

Individual advice

Do you have any questions regarding our reusable load carriers?

Then please get in touch. Our experts will be happy to advise you individually and help you find the solution you need.

Oliver van Neerven

Authorised Representative | Head of Project Management