The customised solution from WALTHER plays an important part in semi-automated picking at Müller and in the smooth delivery to its large number of stores.

Folding boxes made of plastic in use at Müller

Müller

The "Müller tower" in operation

Semi-automated picking in the central warehouse

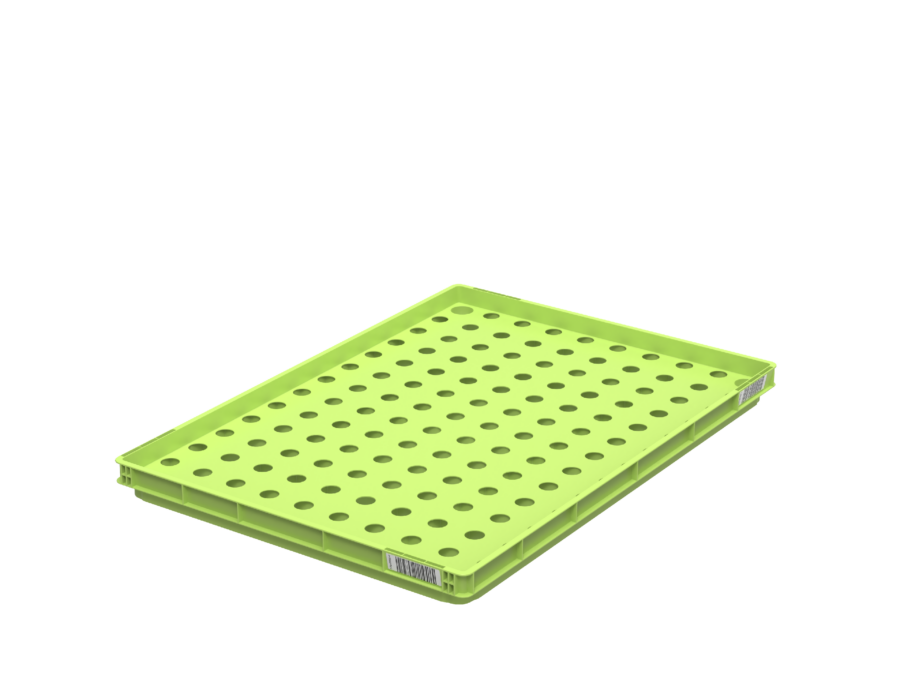

In Müller's department stores, well over 100,000 different products - ranging from mascara to children's bicycles - have to be transported from the central warehouse in Ulm to the more than 900 German and foreign branches. In order to supply the growing number of branches quickly and effectively, Müller introduced semi-automated order picking in 2006. Müller switched from the previously used bin containers to WALTHER folding boxes.

Individual colours and different markings

With the combination of folding boxes and folding frames in only two base sizes, as well as dollies and hooded lids, almost all Müller articles have been arriving at the branches in the so-called "Müller towers" ever since - and picked exactly in such a way that the employees on site can assign all towers to defi ned branch areas and categories of goods. Orange boxes are designed for the transport of standard products, the yellow ones for post and the red ones for hazardous goods. These goods are particularly protected by their hinged lids. The light grey boxes are folding frames or collars, i.e. they have a removed base, and thus double the usable interior space of the box underneath in order to be able to transport larger items.

In addition to the colours, picking is supported by a range of markings: An in-mould label is placed on the frame and the upper side part to clearly identify the boxes with two scanner orientations. Of course, the Müller logo must be clearly legible - hot-foil embossed on the frame and front part. The safety instructions are also hot-foil embossed on the front part of the dangerous goods box.

Special stacking grooves for safe double-stack transports

Another special Müller feature: Several dollies with different folding boxes can be safely stacked on top of each other in a double stack - for this purpose, the lids have special stacking grooves on which even loaded dollies can stand safely without any risk of slipping.

The result of the Müller tower: The distances for stocking are shorter and filling the shelves is faster - an enormous gain in time, which can now be used for customer service.

Folding boxes by WALTHER Faltbox Group

This is how Müller benefits from a customised solution

Individual advice

Do you have any questions regarding our reusable load carriers?

Then please get in touch. Our experts will be happy to advise you individually and help you find the solution you need.