Reusable plant trays in use at Euro Plant Tray

Euro Plant Tray

Sustainable plant logistics

Reusable solution for the green sector

In the cut flower sector, reusable systems have been firmly established for decades, but the situation has been different for potted plants: until the founding of Euro Plant Tray eG, there was no industry-wide, internationally accepted reusable solution for potted plants. It has become clear that reusable systems can only succeed through joint effort: alongside nurseries, the cooperative’s members include wholesalers and horticultural trade organisations, as well as DIY and garden centre chains from across Europe.

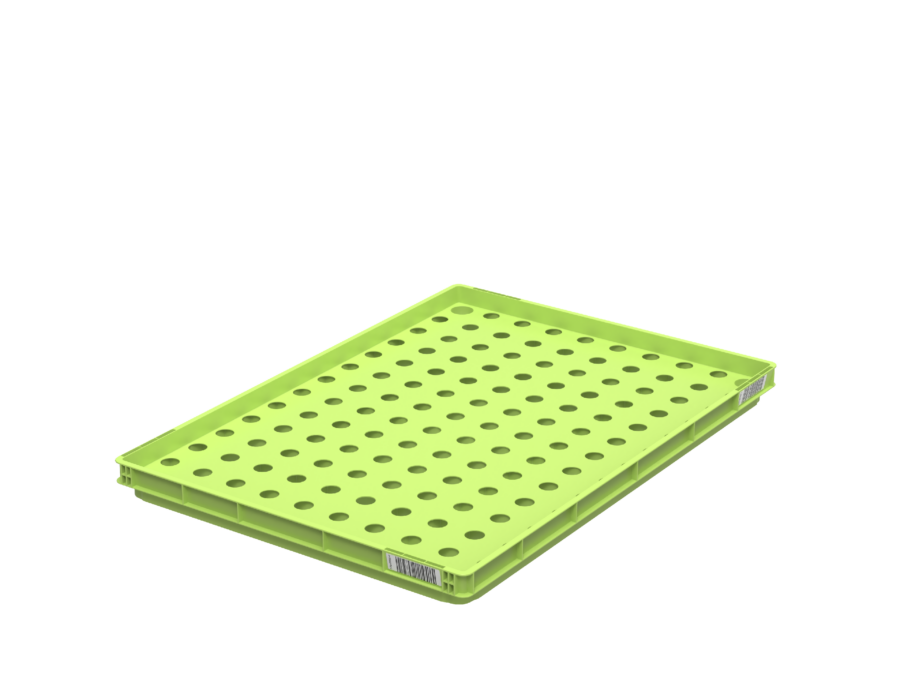

By transitioning to reusable trays, significant resources are saved, while the use of recycled material in production further reduces the demand for virgin material. The various tray models are available to all stakeholders in the supply chain through a rental system. The EPT 777 model was developed and manufactured by WALTHER Faltbox Group. It is designed to hold ten top-heavy plants with a pot diameter of 12 cm, making it primarily used in the indoor plant segment.

Standardisation for compatibility

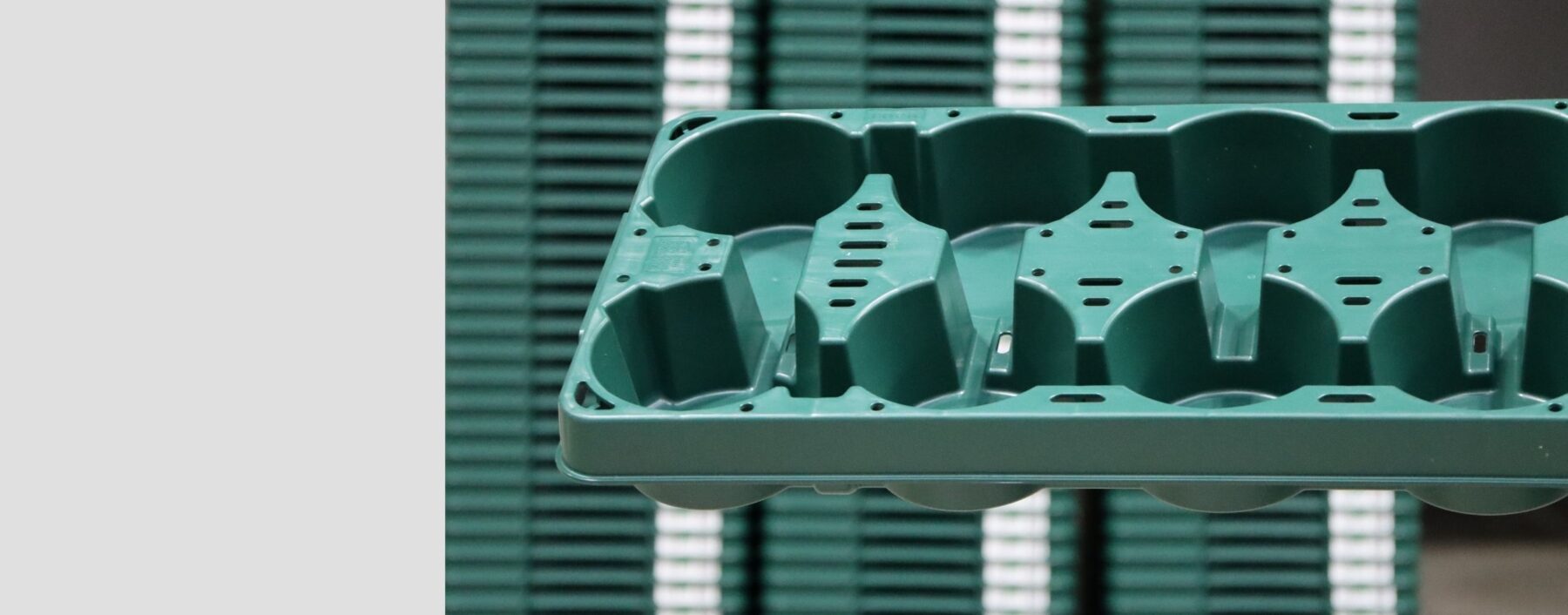

To accommodate the wide variety of plant pots, the design was developed to ensure that as many indoor plant pot types available on the market as possible fit securely in the trays. In addition, the trays are precisely matched to the industry-standard load carriers, the CC containers. To ensure maximum efficiency in return transport and empty storage, we focused on high dimensional stability and stackability so that 666 trays fit on a single Euro pallet.

To ensure that the newly developed design meets practical requirements and is compatible with the different pot types, WALTHER Faltbox Group produced a small series of 20,000 trays. They were thoroughly tested before series production began early 2025.

Especially during the development phase, we worked closely with the experts at WALTHER Faltbox Group. There were many different requirements for our Euro Plant Tray that had to be met. Thanks to extensive testing phases, we were able to ensure reliable performance of the trays within the supply chain. We also benefited from WALTHER Faltbox Group’s expertise during subsequent series production.

Secure transport throughout the entire supply chain

Robust design for easy and long-term use

The reusable trays stand out for their stability, offering easy handling: transport pallets made of thin plastic tear quickly, making them unusable and creating sharp edges. They are also less stable and provide less protection for the goods. The Euro Plant Trays, on the other hand, withstand heavy loads, making them more secure and user-friendly.

The advantage of the reusable system increases with every use, as no new trays need to be produced and material consumption is therefore reduced. With a lifespan of more than ten years and at least 100 cycles, the Euro Plant Trays are particularly durable. After use, the material is recycled and used for the production of new load carriers.

Reliable traceability

Reusable plant trays by WALTHER Faltbox Group

This it how Euro Plant Tray eG benefits from a customised solution

Individual advice

Do you have any questions regarding our reusable load carriers?