Optimised warehouse management with smart identification

Optimised warehouse management

Smart labelling

Customised, automated and digitally traceable identification

RFID: digital traceability with maximum security

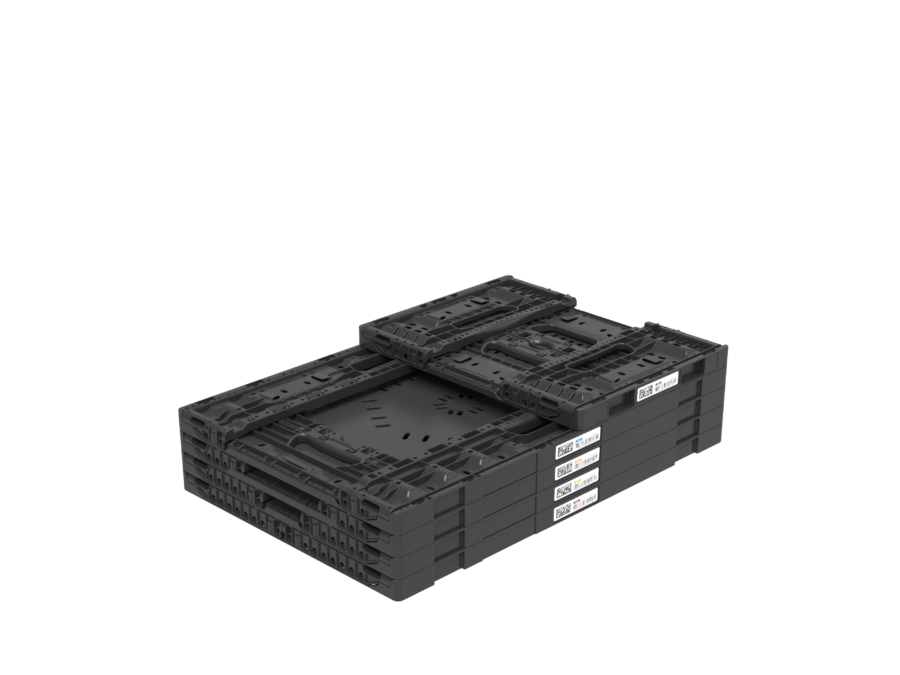

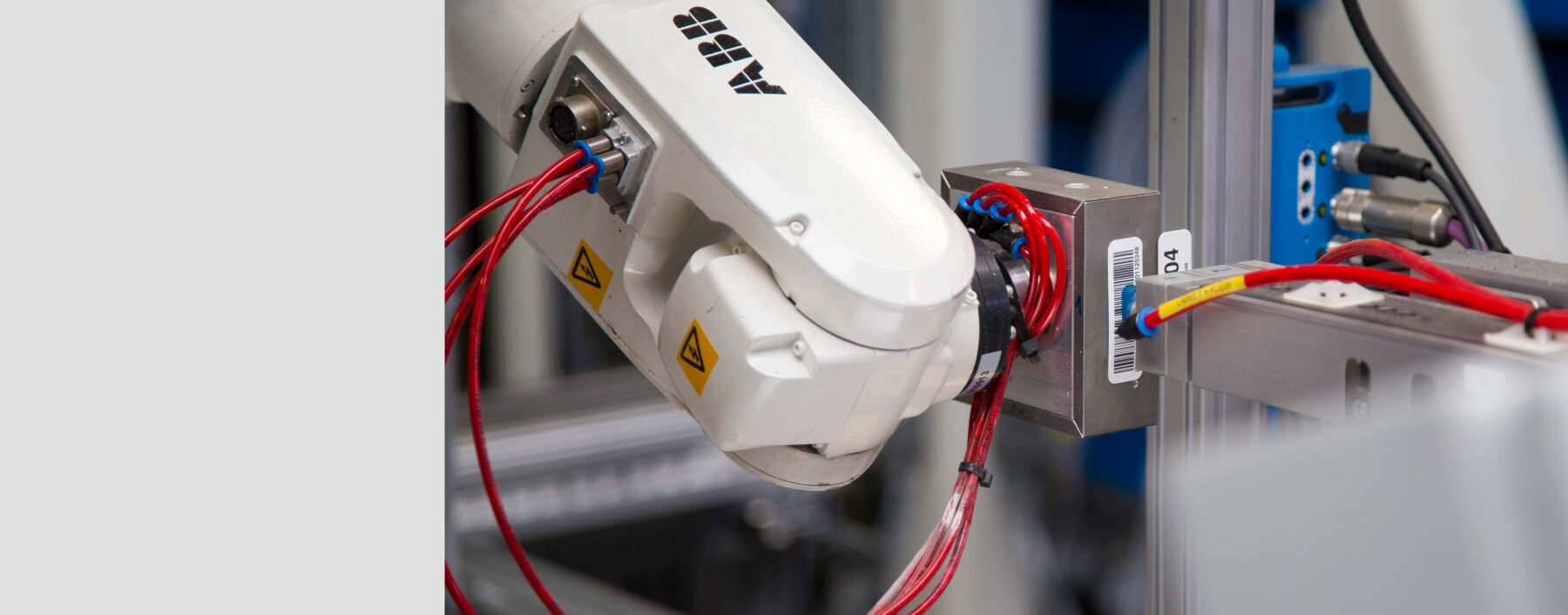

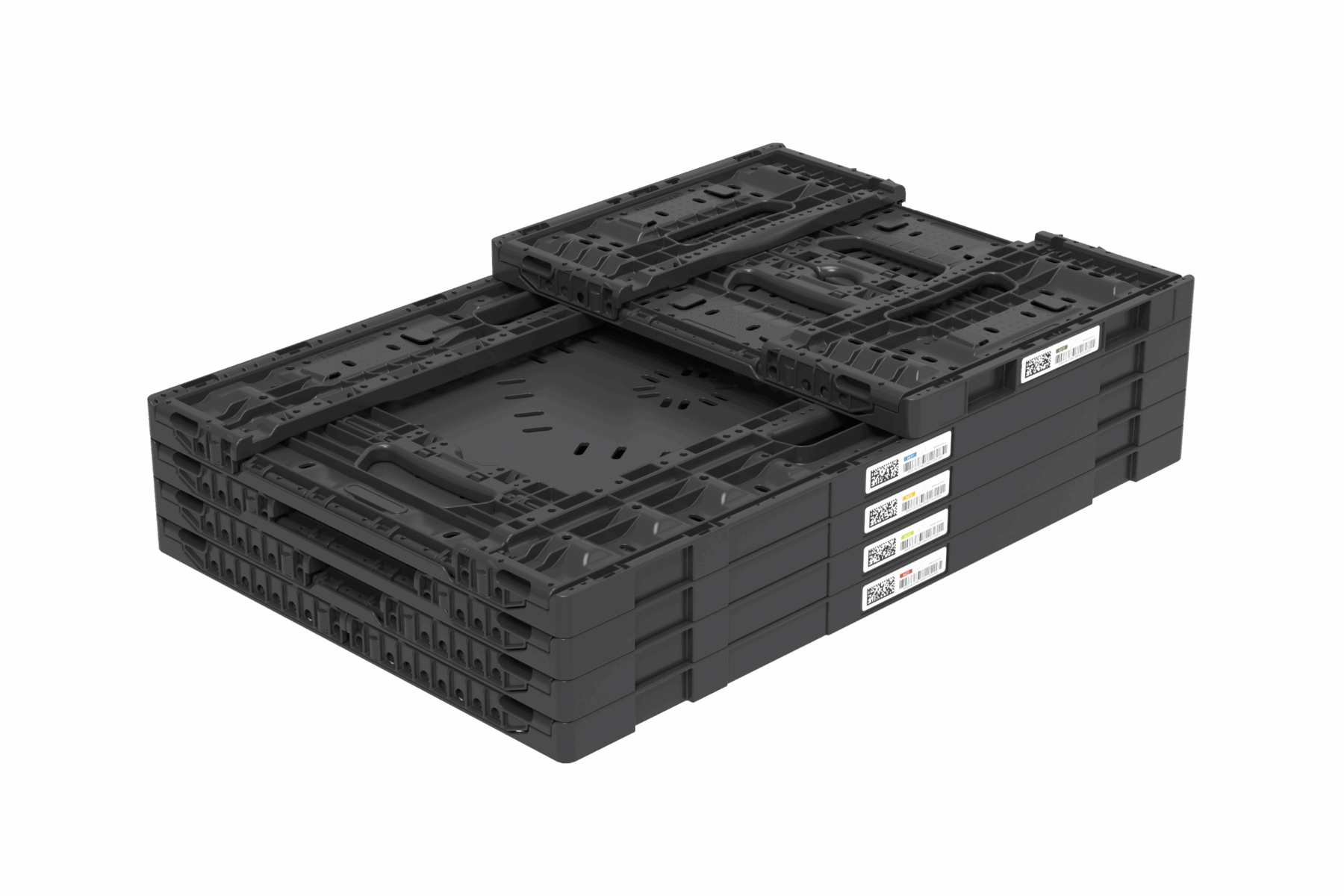

Modern logistics requires seamless traceability. One of the most advanced labelling options currently available: RFID In-Mould labels. With RFID In-Mould labelling, WALTHER enables the complete digital identification of reusable load carriers – from goods receipt through storage and transport to reintegration into the cycle.

The RFID technology is embedded directly during the injection moulding process and tested fully automatically. The advantages: RFID In-Mould labels are tamper-proof, permanently readable and seamlessly integrable into automated systems. Complemented by barcodes and QR codes, the solutions offer flexible application – regardless of existing infrastructure.

Smart labelling solutions enhance the efficiency of automated logistics processes by reducing errors, saving time and increasing transparency across the entire supply chain.

The right identification solution for every application

Labelling techniques

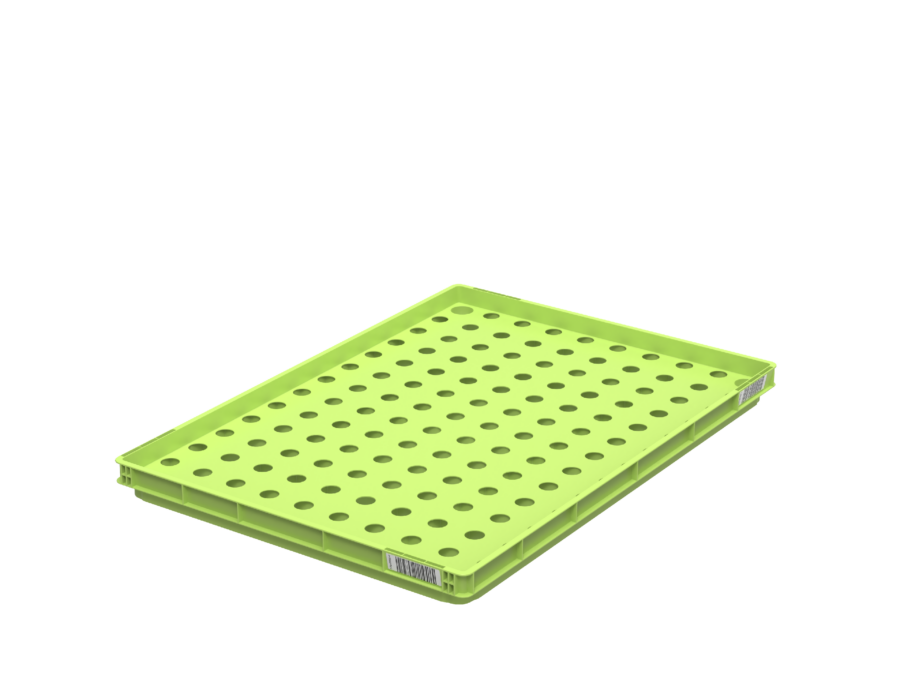

RFID In-Mould label

Barcode In-Mould label

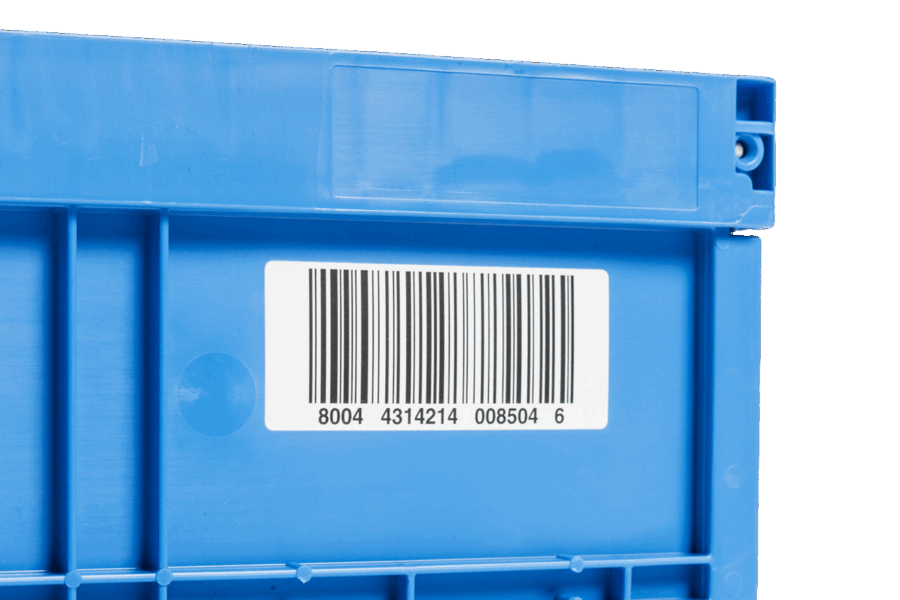

Self-adhesive barcode label

Custom and decorative labels

Intelligent load carriers from WALTHER

All the benefits of smart labelling at a glance

Packaging identification in line with the

EU Packaging and Packaging Waste Regulation

Our solutions already meet these requirements today – through RFID In-Mould labels, barcodes or durable embossing. This enables efficient traceability within the cycle and ensures that companies are optimally positioned in technical, legal and logistical terms, while also improving storage processes.

Individual advice

Do you have any questions regarding our reusable load carriers?

Many of our customers are facing the challenge of digitalising logistics processes and efficiently identifying their reusable load carriers. The WALTHER Faltbox Group supports them with expertise, experience and customised solutions.

Get in touch – we'll find the right solution for your specific requirements.

Oliver van Neerven

Director Projects & Technology