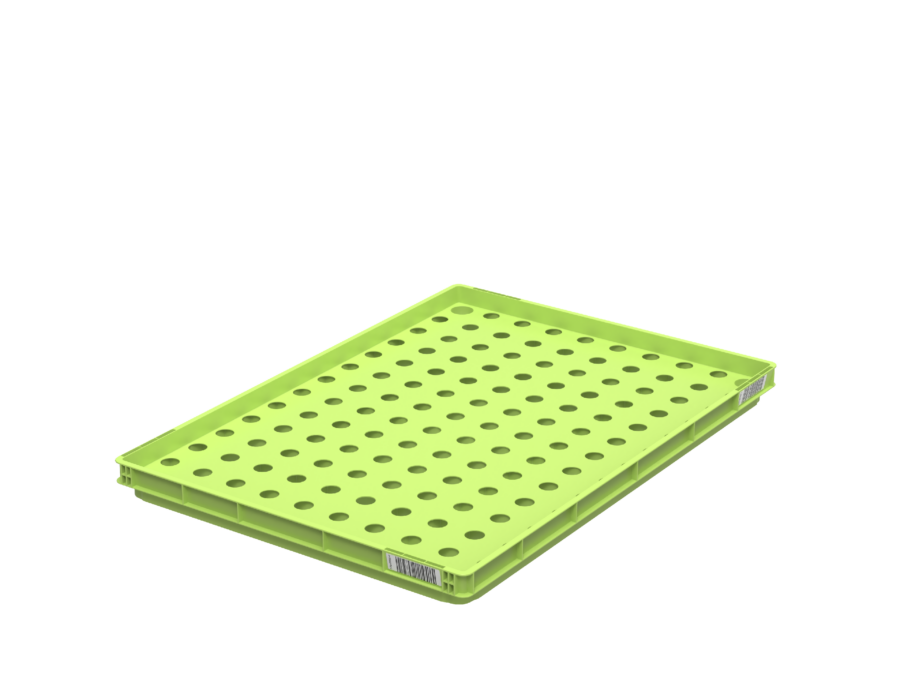

Special folding and collapsible boxes as well as trays from WALTHER Faltbox Group are in use in fully and semi-automated warehouses.

Automated storage technology: Load carriers for warehouses

Automated storage technology

Specific requirements

Our load carriers for modern, automated storage technology

Digitisation and Industry 4.0 have long since entered the world of logistics today. Fully automated warehouses are not only the technology of the future, but are already established worldwide today. Especially when using automated processes, work with robots, stack handling and kilometre-long conveyor lines, the load carrier used must be 100 per cent reliable.

Load carriers as controlling element

Today, load carriers are a moving part of the computer-controlled ecosystem within the warehouse. As soon as the goods are received, they are transferred onto or into the corresponding load carriers and then stored. Once the goods have been placed on or in the load carrier, the system knows its location and which goods it contains at all times. Further information can also be stored and retrieved via the specific barcode. Conveyor belts, automated storage and retrieval systems, or roller belts take the load carriers to their temporary storage location. This space is automatically calculated and assigned by the system depending on the type of goods. A variety of factors are taken into account, for example how often the item is retrieved.

Reliability for complex processes

Beside fully automated warehouses, in which the goods are picked autonomously by robots and other handling systems, semi-automated processes have also become established. The goods are driven in their containers to the picking line where they are then picked. The required items are taken from the container and the container is sent back on its journey into the storage system to its new storage location.

The requirements for the load carriers on automated conveyor systems are varied, and a seamless workflow of the complex processes is essential.

Customer examples

Reference projects

Individual advice

Do you have any questions regarding our reusable load carriers?

Then please get in touch. Our experts will be happy to advise you individually and help you find the solution you need.

Thomas Schleisick

Head of Business Development

Our online shop

You can find standard size folding boxes in our online shop

It does not always have to be a customised product. In our online shop, you will surely find the right solution for your needs from our standard range.