Our high-quality, custom-developed plastic parts are precisely tailored to the specific needs of our customers.

Technical parts

Technical parts

Solutions that fit perfectly

Technical plastic parts for versatile applications

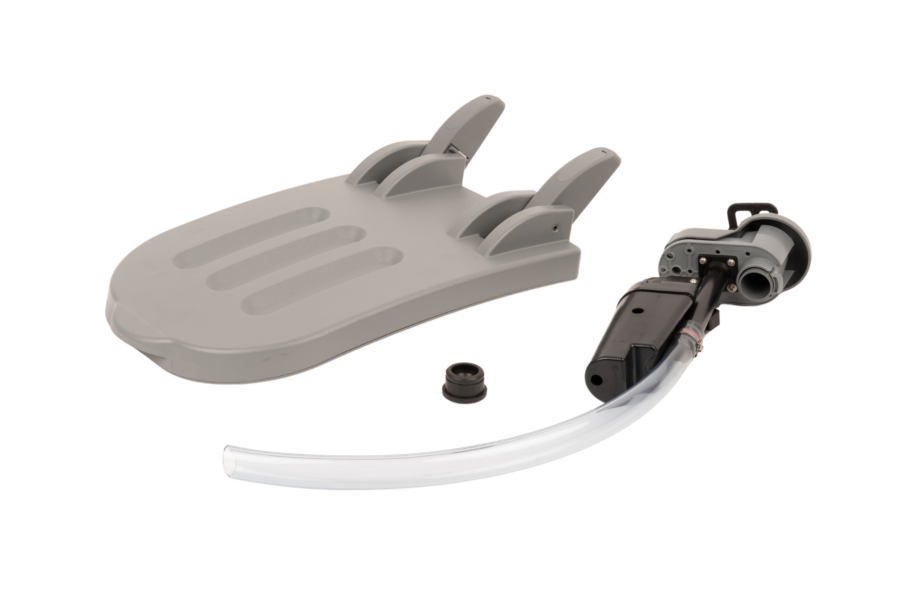

We manufacture precise technical plastic parts for a wide range of applications, supplying customers across diverse industries. As a manufacturer of plastic parts, we draw on over 55 years of experience. Starting with religious items, we now utilize our comprehensive range of injection moulding machines to produce a broad portfolio of technical plastic parts in various sizes and materials.

The injection moulding process enables us to manufacture anything from small sealing rings with diameters of just a few centimetres to large parts weighing several kilograms. In addition to designing and producing plastic parts, we also offer assembly services, where we integrate these parts directly into complete assemblies for our customers.

Features and benefits

What makes our technical parts special

Wide variety of shapes and sizes

With shot weights ranging from just a few grams to several kilograms, we offer technical parts in all conceivable shapes and sizes, from cover elements and seals to mechanical components.

Lightweight construction

Thanks to the low weight of our plastic parts, they are particularly efficient in use, being significantly lighter than metal alternatives. This results in reduced material consumption and lower energy costs, which helps to minimise the carbon footprint of the components.

Customised solutions

Our customised plastic parts are precisely adapted to meet the specific requirements of our customers. With our in-house toolmaking capabilities, we can shape and structure components according to individual needs. We select the plastic based on its mechanical, thermal, and chemical properties.

Durable and robust

Our technical plastic parts are resistant to wear and maintain their shape and stability even under long-term use in various environments. This reduces the need for frequent replacements or repairs, allowing for cost-efficient and sustainable use over many years.

Cost and resource efficiency

Our efficient manufacturing processes keep production costs low. At the same time, the lightweight design and high durability minimise material usage. As a result, our technical plastic parts are particularly economical and resource efficient.

Technical plastic parts by WALTHER Faltbox

All the advantages of our technical plastic parts at a glance

Individual advice

Do you have any questions regarding our product range?

Then please get in touch. Our experts will be happy to advise you individually and help you find the solution you need.

André Hecker

Customer examples

Reference projects

Hako

Custom components for diverse applications

Learn more about the use of our technical parts at Hako and how the machinery manufacturer benefits from our customised solutions.